Instrumentation

Sanitary instrumentation encompasses a range of equipment and devices used to measure, monitor, and control hygiene and sanitation parameters in various settings, playing a vital role in maintaining sanitary conditions and promoting public health.

Instrumentation for Use in Hygienic Applications

Sanitary instrumentation encompasses a wide range of devices used for measurement, control, monitoring, and analysis purposes in hygienic processes. These products are designed for use in industries where maintaining strict hygiene and preventing contamination are of paramount importance. These industries include pharmaceuticals, biotechnology, food and beverage, cosmetics, and other sectors that deal with sensitive or consumable products.

By utilizing sanitary instrumentation, industries can maintain product integrity, enhance quality control, and adhere to strict regulatory requirements, ultimately safeguarding consumer safety and satisfaction.

Connect with a Casella team member to discuss your instrumentation needs!

Our Products Include:

Sanitary Flow Measurement

Sanitary Sight Glasses

Pressure Gauges

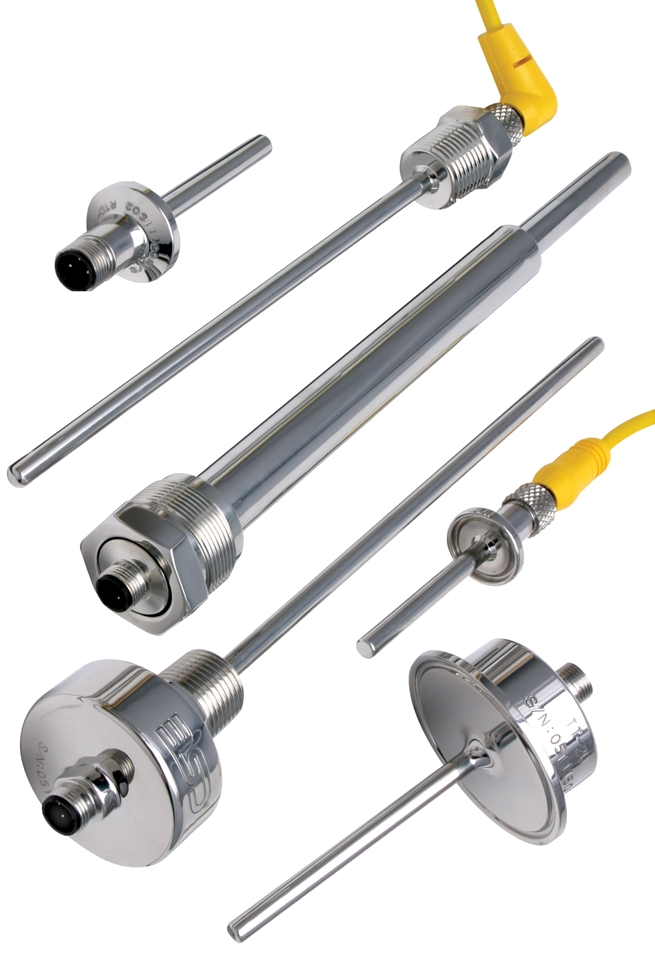

Sanitary Temperature Sensors

& many more!

FEATURED

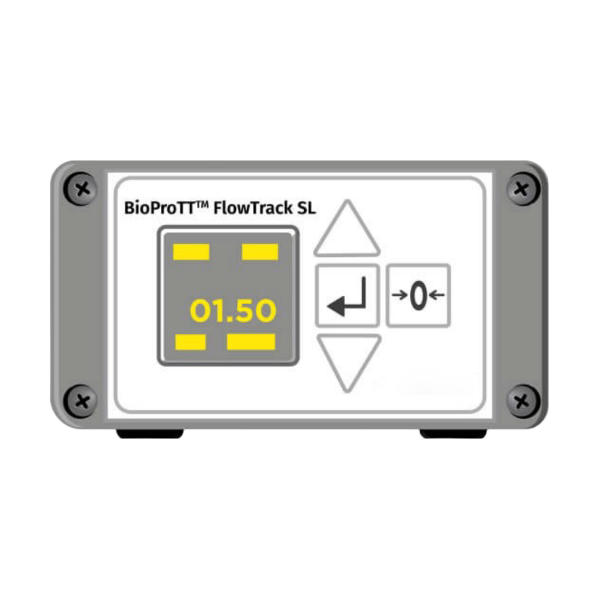

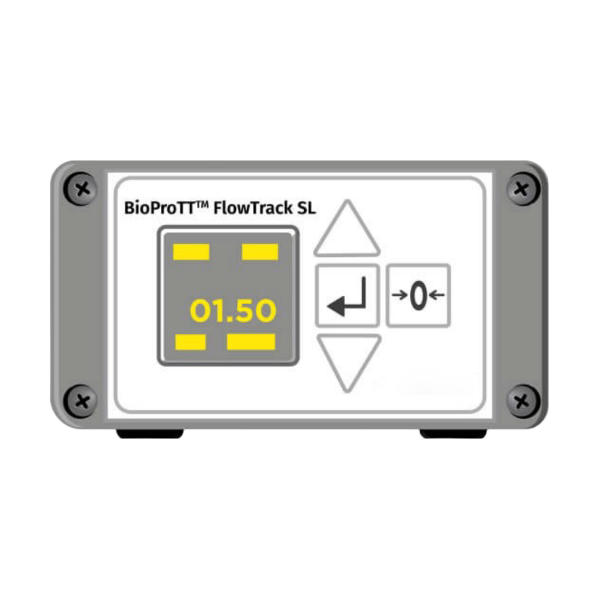

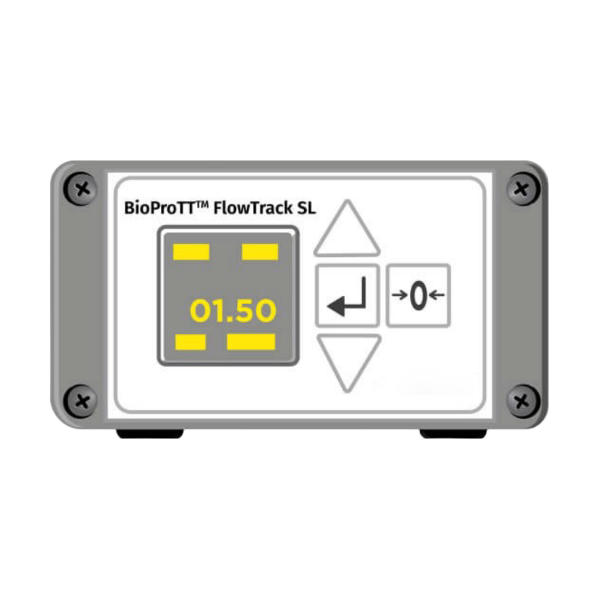

Flowmeters

Flowmeters are devices used to measure the flow rate and volume of fluids in various industries and applications. They offer accurate and precise measurements, real-time monitoring, low maintenance requirements, and a wide range of applications. Flowmeters can be integrated into existing systems, reducing downtime and costs. They are essential for maintaining product quality, optimizing system performance, and ensuring regulatory compliance.

Additionally, flowmeters come in a variety of types, designs, and sizes to fit different applications, such as liquid flow measurements. Some types of flowmeters, like ultrasonic and clamp-on, are non-invasive, which means they can be installed without disrupting the flow of fluids. Flowmeters are crucial tools for a range of industries, from chemical processing and water treatment to energy management and research.

NEW

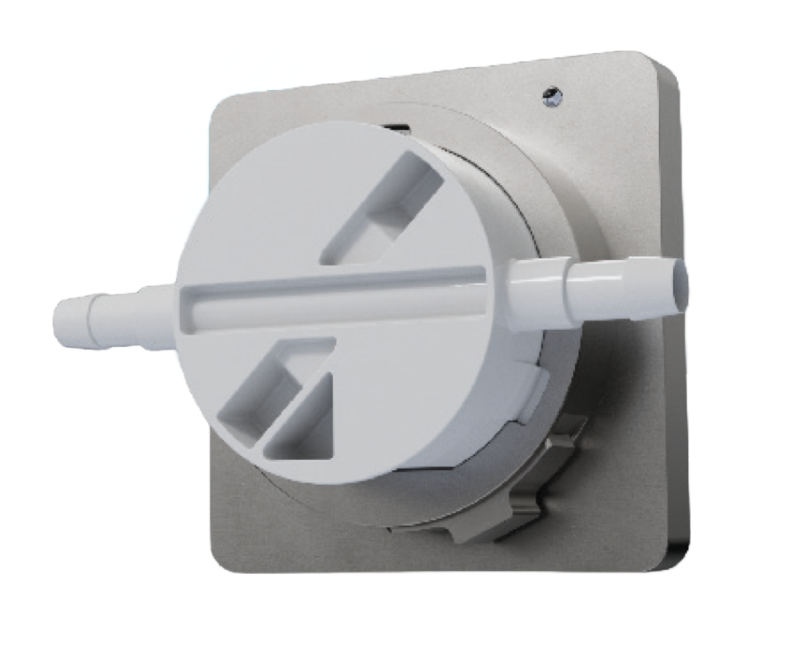

BioProTT™ FlowSU System

An innovative flow module for use with em-tec flow meter

Introducing the BioProTT™ FlowSU System, an innovative solution for measuring flow in single-use biopharmaceutical applications. This cutting-edge system includes a unique disposable sensor, which eliminates the need for calibration, along with a reusable holder profile that is effortless to mount and incorporates integrated electronics.

The Importance of Instrumentation Accuracy

The accuracy of sanitary instrumentation is crucial for several reasons. It directly impacts health and safety by ensuring effective monitoring and maintenance of sanitation and hygiene measures. Compliance with stringent regulations and standards in industries like healthcare, food processing, and water treatment relies on accurate instruments. Failure to meet these requirements can lead to legal consequences and reputational damage.

Accurate instrumentation is vital for quality control, allowing industries to meet standards and produce safe products. It enables process optimization by measuring critical parameters and reducing waste. Data-driven decision-making is facilitated by reliable measurements, enabling trend analysis and timely corrective actions. Regular calibration and maintenance ensure instrument accuracy and reliability, reducing the risk of failures.

Overall, accurate sanitary instrumentation is essential for maintaining sanitary conditions, protecting public health, complying with regulations, ensuring product quality, optimizing processes, and making informed decisions. It is a crucial aspect of industries where hygiene, sanitation, and public health are paramount.

Our Trusted Partners

Flowmeters: The Key to Maintaining Process Control and Improving Product Quality in Pharma and Biotech Manufacturing

In the world of pharmaceutical and biotech manufacturing, precision and reliability are paramount. Every step, every measurement, and every component counts toward ensuring product quality and maintaining stringent process control.

Speak with a Dedicated Casella Representative

Casella has developed an extensive product offering through partnerships with industry leading sanitary process manufacturers. With extensive experience in the industry, count on us to meet your needs while improving your facility’s operation and efficiency.